Symplify Now! easily accessible on the NI CompactRIO

Symplify Now! is a robust and versatile test automation and data acquisition solution, engineered to run directly on NI CompactRIO hardware.

Designed for maximum flexibility, Symplify Now! enables fully autonomous operation, allowing the system to function independently without the need for a connected PC or any user interface. This makes it exceptionally well-suited for embedded, remote, and industrial environments where long-term reliability and operational independence are essential.

One of its most valuable features is that Symplify Now! does not require any coding for setup or operation, streamlining deployment for users of all technical backgrounds. The solution excels particularly at automated data logging, which can be trigger-based and initiated from any input, making it effortless to capture.

Alongside data logging, Symplify Now! skillfully manages real-time control and sequencing tasks, all with minimal setup and an intuitive workflow that empowers users to achieve more with less effort.

Product overview

Symplify Now! integrates seamlessly with a broad spectrum of NI digital and analog I/O modules, mainly 92xy, 93xy, 94xy, and 986x (XNET), ensuring your existing infrastructure remains compatible and scalable.

Leveraging the intuitive interface of NI MAX for all DAQ configurations, users can quickly access, configure, and optimize each module’s advanced features for more complex setups. This means engineers and operators can transition effortlessly, with minimal learning curve or downtime, to a more powerful and flexible environment.

With interaction capabilities between a Windows PC and CompactRIO hardware, Symplify Now! empowers users to monitor live data feeds and adjust parameters such as trigger levels on the fly, responding instantly to changing conditions on the plant floor or in the field.

The platform also supports distributed CompactDAQ chassis, allowing data logging and control for components spread across various sites, making it perfect for large-scale or geographically dispersed facilities. This distributed capability promotes efficiency, reliability, and centralized oversight wherever your operations demand it.

No limit to customization

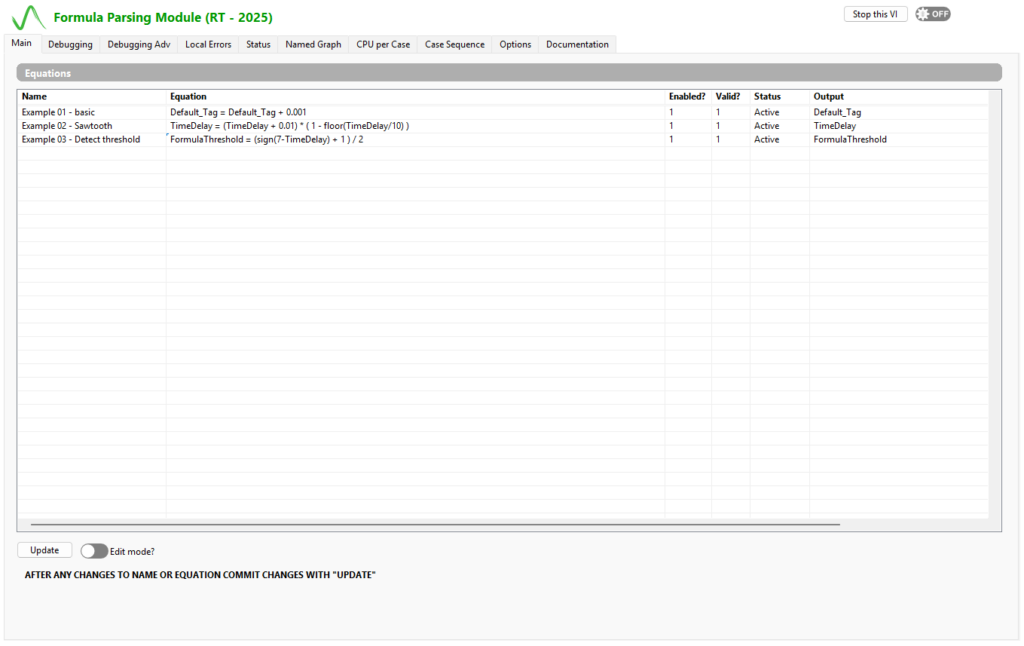

Engineered with openness and extensibility at its core, Symplify Now! is ready to handle advanced and custom requirements. Python scripts can be executed alongside the system for sophisticated reporting, powerful data analysis, or complex decision-making logic—without the need for extensive redevelopment.

For truly specialized applications, most of the source code is accessible (with LabVIEW and LabVIEW RT licenses), enabling the addition of new drivers, the creation of custom control algorithms, edge processing of your data and many more. This flexibility ensures that Symplify Now! can be tailored to fit current and future needs as your organization grows or evolves.

Key Features

No-Code Configuration

Configure sampling rates, measurement types, and scaling using NI DAQmx and NI MAX—leveraging proven NI driver flexibility without added complexity. Adjust what to log, when to log, and how outputs behave—all at runtime—without redeploying code.

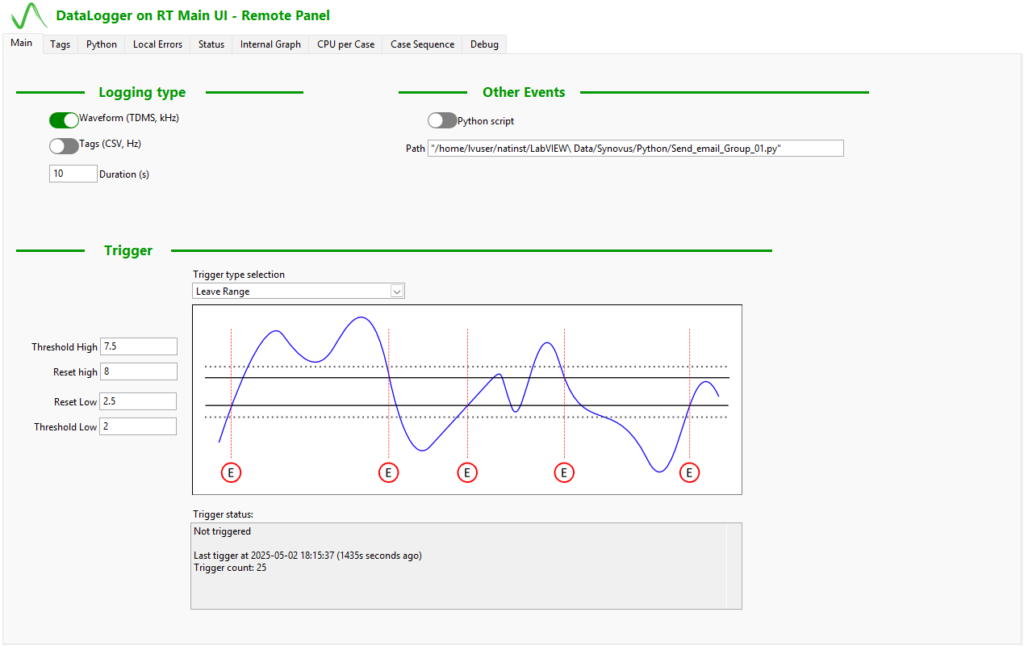

Advanced Triggering

Every I/O channel can be used for triggering, logging, or control, enabling more responsive and intelligent data acquisition workflows.

Full Headless Operation

Operates on CompactRIO 904x/905x with DAQmx, logging to SD cards, USB, or internal memory—ideal for remote or embedded setups. Storage space can exceed 1TB with external drive.

Real-Time Monitoring & Alerts

Built-in diagnostics, email/SMS alerts, and MQTT reporting keep you informed—provided the CompactRIO has internet access.

Fast Data Review

All log files are compatible with Symplify’s PC-based viewers, enabling data analysis up to 100x faster than Excel. Logged files can also be viewed and processed in Matlab and NI Diadem.

Python expansion

Python scripts can read and write any system variable, allowing you to automate routines such as calibration and generate custom reports. Notifications can also be triggered, enabling the system to contact an engineer in real-time whenever attention is needed.

Modular and expandable Architecture

Built on scalable LabVIEW modules for logging, calibration, and communication—easily expandable for custom workflows. Most of the source code is also available to customers to make any change and recompile the Real-Time application.

Technical Specifications

Symplify Now! RT 25.0 supports:

- Chassis: NI CompactRIO 904x/905x

- Modules: 92xy, 93xy, 94xy (NI DAQmx), 986x (NI-XNET)

- Maximum data rate: 1MS/s (1GS/s on NI PXI version)

- Data Bandwidth: up to 64 channels at 50kS/s/ch (cRIO dependant)

- Logging Formats: CSV or TDMS

- Storage Options: SD card, USB, external drives, internal memory

- Triggering: Per-channel, formula-based, scriptable

- Control: Events based and execution of sequences like temperature ramps or RPM cycles (with scripting)

- Integration: Python scripting, MQTT, email/SMS alerts

- Customization: Access to application source code for LabVIEW-based extensions

- Protocols: Modbus RTU/TCP, EthernetIP, CAN, OPC UA (may require customization)

Watch it in action

Typical Applications

Automotive Field Trials

Validate components under real-world conditions with deterministic control and remote diagnostics. Ideal for off-highway and heavy-duty vehicle testing.

Field Data Acquisition

Deploy CompactRIO as a standalone logger with real-time alerts and remote access, perfect for field installations. With data encryption and reliable performance in harsh environments, NI cRIO with Symplify Now! is an optimal choice for field installations that demand durability, security, and even advanced analytics.

Industrial Automation

Replace or complement PLC-based systems with intelligent control and logging. Symplify Now! can act as an industrial controller with flexible I/O and trigger logic and maintain rigorous data records for compliance and optimization purposes.

Long un-attended tests

Confidently run weeks and months long tests in the lab without worrying about updates or restarts. Push data to the cloud to monitor the test procedures from anywhere, directly on your phone.

Frequently Asked Questions

Do I need LabVIEW to use Symplify Now!?

No. LabVIEW is only required for adding new drivers or implementing complex closed-loop control. Most control applications under 4 Hz (closed-loop) or 20 Hz (open-loop) are accessible without programming.

Can I run Symplify Now! on PXI systems?

Yes, it supports Linux RT PXI systems, though CompactRIO is the primary target due to its smaller and rugged form factor.

Is Python required?

No, but Python integration is available for teams that want to automate test plans and runtime logic.

Can Symplify Now! act as an industrial controller (PLC)?

Symplify Now! on the CompactRIO can perform tasks similar to traditional PLC with its flexible I/O, trigger logic, and deterministic control. It is also capable of communicating with PLC over many industrial protocols. However, it cannot be programmed traditional languages (such as IEC 61131-3) Reach out to our engineers to discuss your specific application.

What are the differences between Symplify Now! on the CompactRIO and Symplify Now! on my Windows machine?

The application on the CompactRIO can run tasks more deterministically and is not intended to have a user interface. It can use most of the same features and instruments drivers as the PC version but more reliably over longer periods of time.

Do triggers have to come from specific edge on analog inputs?

No, triggers can come from any Tag in the system, not only analog inputs. Triggers can even come from an equation using multiple inputs. The basic types of triggers include High / Low / Enter range / Leave range but more complex ones can be created within the application, or through scripts.